Study of media optimization and kinetic modeling of l-methioninase from Pseudomonas stutzeri

Research Articles | Published: 20 June, 2019

First Page: 370

Last Page: 380

Views: 3645

Keywords: l-Methioninase, Pseudomonas stutzeri , Media component, Statistical optimization, Kinetic modeling

Abstract

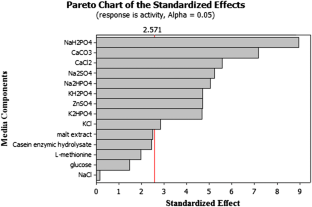

In this study, Pseudomonas stutzeri has been explored as new bacterial strain for producing intracellular l-methioninase. Kinetic modeling and optimization of fermentation conditions are crucial parameters for improving production of l-methioninase. Response surface methodology has been employed as fast efficient technique for investigating the interactive effect of culture condition parameters for l-methioninase. Plackett–Burman design was first employed for screening significant variables for production media components including glucose, l-methionine, NaCl, malt extract and casein enzymic hydrolysate. The optimal level of these significant media components was further optimized using Central composite design. The high value of determination of coefficient (R2 = 0.95) showed the good fitness of these statistical models for explaining the relationship between variables and response. The optimum values for the investigated variables were obtained as 5% glucose, 0.25% l-methionine, 0.2% malt extract, 1% casein enzymic hydrolysate and 1% NaCl. The maximum production of l-methioninase was obtained as 240.97 U/l after performing the experiments at these optimum data variables, which was increased by 1.61-fold in compare to classical method. The kinetic study was further performed at these optimum media components and the production of l-methioninase was found as non-growth associated behavior. Logistic equation and modified Luedeking–Piret equation were further employed to develop mathematical model for growth kinetic and production kinetic. These results would be significant for large scale production of these enzymes using bioreactors in industry.

References

- Baskar G, Renganathan S (2012) Optimization of l-asparaginase production by Aspergillus terreus MTCC 1782 using response surface methodology and artificial neural network-linked genetic algorithm. Asia Pac J Chem Eng 7(2):212–220

- Cellarier E, Durando X, Vasson MP, Farges MC, Demiden A, Maurizis JC, Chollet P (2003) Methionine dependency and cancer treatment. Cancer Treat Rev 29(6):489–499

- Cutchins EC, Doetsch RN, Pelczar MJ Jr (1952) The influence of medium composition on the production of bacterial lipase. J Bacteriol 63(2):269

- Dutta JR, Dutta PK, Banerjee R (2004) Optimization of culture parameters for extracellular protease production from a newly isolated Pseudomonas sp. using response surface and artificial neural network models. Process Biochem 39(12):2193–2198

- El-Naggar Nel-A, Moawad H, El-Shweihy NM, El-Ewasy SM (2015) Optimization of culture conditions for production of the anti-leukemic glutaminase free l-asparaginase by newly isolated Streptomyces olivaceus NEAE-119 using response surface methodology. BioMed Res Int. https://doi.org/10.1155/2015/627031

- Fogarty WM, Kelly CT (1990) Recent advances in microbial amylases. In: Fogarty WM, Kelly CT (eds) Microbial enzymes and biotechnology. Elsevier Applied Science, New York, pp 71–132

- Hymavathi M, Sathish T, Brahmaiah P, Prakasham RS (2010) Impact of carbon and nitrogen sources on l-asparaginase production by isolated Bacillus circulans (MTCC 8574): application of saturated Plackett–Burman design. Chem Biochem Eng Q 24(4):473–480

- Khalaf SA, El-Sayed AS (2009) l-Methioninase production by filamentous fungi: I-screening and optimization under submerged conditions. Curr Microbiol 58(3):219–226

- Kharayat B, Singh P (2018) Microbial production of L-methioninase and its biotechnology application. Int J Recent Sci Res 9(8C):28439–28446

- Kiruthika J, Saraswathy N, Murugesan S (2018) Maximizing l-glutaminase production from marine Bacillus subtilis JK-79 under solid state fermentation. Afr J Biotechnol 17(9):288–305

- Kreis W, Hession C (1973) Isolation and purification of l-methionine-α-deamino-γ-mercaptomethane-lyase (l-methioninase) from Clostridium sporogenes. Can Res 33(8):1862–1865

- Li XY, Liu ZQ, Chi ZM (2008) Production of phytase by a marine yeast Kodamaea ohmeri BG3 in an oats medium: optimization by response surface methodology. Biores Technol 99(14):6386–6390

- Luedeking R, Piret EL (1959) A kinetic study of the lactic acid fermentation. Batch process at controlled pH. J Biochem Microbiol Technol Eng 1(4):393–412

- Moser A, Steiner W (1975) The influence of the term k d for endogenous metabolism on the evaluation of Monod kinetics for biotechnological processes. Eur J Appl Microbiol Biotechnol 1(4):281–289

- Muralidhar RV, Chirumamila RR, Marchant R, Nigam P (2001) A response surface approach for the comparison of lipase production by Candida cylindracea using two different carbon sources. Biochem Eng J 9(1):17–23

- Pinnamaneni N, Funderburgh JL (2012) Concise review: stem cells in the corneal stroma. Stem Cells 30(6):1059–1063

- Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrika 33(4):305–325. https://doi.org/10.2307/2332195

- Ruchi G, Anshu G, Khare SK (2008) Lipase from solvent tolerant Pseudomonas aeruginosa strain: production optimization by response surface methodology and application. Biores Technol 99(11):4796–4802

- Sato D, Nozaki T (2009) Methionine gamma-lyase: the unique reaction mechanism, physiological roles, and therapeutic applications against infectious diseases and cancers. IUBMB Life 61(11):1019–1028

- Shanthi V, Roymon MG (2015) Response surface optimization of xylanase production by indigenous thermoalkalophillic Bacillus sp. Afr J Microbiol Res 9(27):1699–1705

- Sharma B, Singh S, Kanwar SS (2014) l-Methionase: a therapeutic enzyme to treat malignancies. BioMed Res Int. https://doi.org/10.1155/2014/506287

- Singh P, Kharayat B (2018) Statistical optimization of reaction condition of l-methioninase from Bacillus subtilis. Res Rep 2:e1–e9. https://doi.org/10.9777/rr.2018.10332

- Subba Rao C, Sathish T, Pendyala B, Kumar TP, Prakasham RS (2009) Development of a mathematical model for Bacillus circulans growth and alkaline protease production kinetics. J Chem Technol Biotechnol Int Res Process Environ Clean Technol 84(2):302–307

- Tan Y, Sun X, Xu M, An Z, Tan X, Tan X, Hoffman RM (1998) Polyethylene glycol conjugation of recombinant methioninase for cancer therapy. Protein Expr Purif 12(1):45–52

- Tanaka H, Esaki N, Soda K (1985) A versatile bacterial enzyme: l-methionine γ-lyase. Enzyme Microbial Technol 7(11):530–537

- Varalakshmi V, Raju KJ (2013) Optimization of l-asparaginase production by Aspergillus terreus mtcc 1782 using bajra seed flour under solid state fermentation. Int J Res Eng Technol 2(09):121–129

- Weimer B, Seefeldt K, Dias B (1999) Sulfur metabolism in bacteria associated with cheese. Antoine van Leeuwenhoek 76:247–261

- Wriston JC, Yellin TO (1973) l-Asparaginase: a review. Adv Enzymol Relat Areas Mol Biol 39:185–248

Author Information

Department of Bioscience and Biotechnology, Banasthali Vidyapith, Tonk, India