Elucidation of optimum culture conditions for cellulase production by thero-tolerant Aspergillus fumigatus isolated from heap of cassava peels

*Article not assigned to an issue yet

Research Articles | Published: 29 April, 2025

First Page: 0

Last Page: 0

Views: 770

Keywords: n Aspergillus fumigatus LC592224, Endoglucanase activity, Β-glucosidase activity, Exoglucanase activity, thermo-tolerant, ITS gene

Abstract

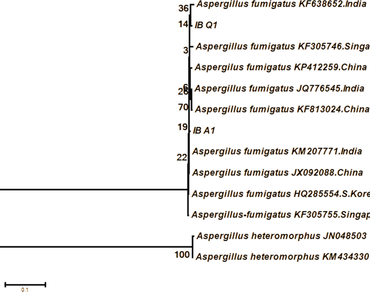

Temperature control is a very important and expensive unit operation in enzyme production. The use of microbial strains that can efficiently produce enzymes over a wide range of temperature will minimize the need for temperature control and thus reduce the cost of production. The aim of this work was to isolate thermo-tolerant organisms from cassava peel and sawdust piles and to optimize cellulase production by the isolates. Out of 50 thermo-tolerant fungi isolated from cassava peels and sawdust piles, two isolates showed good potential for cellulase production and were molecularly identified using ribosomal DNA (rDNA) Internal Transcribed Spacer region (ITS) as Aspergillus fumigatus IB-A1 and Aspergillus fumigatus IB–Q1. The sequences were deposited in DNA Data Bank of Japan (DDBJ) and the European Molecular Biology Laboratory (EMBL). The two organisms, Aspergillus fumigatus IB- A1 and Aspergillus fumigatus IB- Q1 were assigned accession numbers of LC592224 and LC592225 respectively. Endoglucanase, β-glucosidase and exoglucanase production by Aspergillus fumigatus LC592224 was optimized in terms of the initial pH, nitrogen sources, and addition of inorganic salts. In a nutrient broth with peptone as the nitrogen source and at an initial pH of 5.5, the endoglucanase, β-glucosidase and exoglucanase activities were 1.404 ± 0.0789, 1.142 ± 0.09 and 0.828 ± 0.04 U/ml/min respectively after 120 h of cultivation. However, under the optimum culture conditions (pH of 6.0 in a medium containing NaNO3 and CaCl2), the endoglucanase, β-glucosidase and exoglucanase activities increased to 3.211 ± 0.029, 2.501 ± 0.072 and 1.834 ± 0.084 U/ml/min respectively. The results showed that under the optimum culture conditions, the activities of the enzymes are ranked as {endoglucanase} > {β-glucosidase}> {exoglucanase} (p < 0.05).

References

Segneanu AE, Macarie C, Ungureanu M, Balcu I, Gherman V (2013) Comparative study on enzymatic hydrolysis of cellulose. Digest J Nanoma Biostruc 8:1061–1068

Laila N, Siti NF, Md Abdul HS, Lateef AA, Shaiquzzaman S, Norhafizah MZ, Sarker MRK (2021) Cellulase enzyme production from filamentous Fungi Trichoderma Reesei and Aspergillus Awamori in submerged fermentation with rice straw. J Fungi 7:868

Bhardwaj N, Kumar B, Agrawal K (2021) Current perspective on production and applications of microbial cellulases: a review. Biores Bioproc 8:95. https://doi.org/10.1186/s40643-021-00447-6

Yinghui H, Hui Z, Yeledana H, Na S, Wei H, Xiwen J, Kaili D, Xueyan L, Luoyang L, Lujia H, Weihua X (2024) On-site cellulase production by Trichoderma Reesei RutC-30 to enhance the enzymatic saccharification of ball-milled corn Stover. Enzyme Microb Technol 28. https://doi.org/10.1016/j.enzmictec.2024.110530

Diogo R, Beatriz Merchel PP, Aline CC, José Geraldo da CP (2024) Cellulase and Xylanase Enzymes from Trichoderma reesei RUT-C30 Using Pretreated Sugarcane Bagasse in a Biorefinery Environment. Braz Archi of Biol and Technol 67: e24240066, 2024https://doi.org/10.1590/1678-4324-2024240066

Barapatre S, Rastogi M, Nandal M (2020) Isolation of fungi and optimization of pH and temperature for cellulase production. Nat Environ Pollution Technol 19(4):1729–1735

Korsa G, Ronwarh R, Masi C, Ayele A, Haile S (2023) Microbal cellulase production and its potential application for textile industries. Ann Microbiol 73(13) 2023 https://doi.org/10.1186/s13213-023-01715-w

Gautam SP, Bundela SP, Pandey AK, Khan J, Awasthi MK, Sarsaiya S (2011) Optimization for the production of cellulase enzyme from municipal solid waste residue by two novel cellulolytic fungi, Biotechnol Res Internati 2011: ID 810425, 8. https://doi.org/10.4061/2011/810425

Yunus G, Kuddus M (2021) Cold-active microbial cellulase: novel approach to understand mechanism and its applications in food and beverages industry. J Microb Biotech FoodSci 10(4):524–530

Gadow SI, Jiang H, Watanabe R, Li Y (2013) Effect of temperature and temperature shock on the stability of continuous cellulosic- hydrogen fermentation. Bioresour Technol 142:304–311

Gomes J, Steiner W (2004) The bio- catalytic potential of extremozymes. Food Technol Biotechnol 42:223–235

Lynd LR, Weimer PJ, Van Zyl WH, Pretorius IS (2002) Microbial cellulose utilization: fundamental and biotechnology. Microbiol Mol Bio Reviews 66:506–577

Gautam SP, Bundela PS, Pandey AK, Awasthi MK, Saraaiya S (2010) Optimization of medium for the production of cellulase by the Trichoderma viride using submerged fermentation. Internati J Environ Sci 1:656–665

Metzenberg SS (2003) method-Dideoxynucleotide chain termination. http://www.csun.edu/hcbio027/biotechnology/lec3/sanger.htm

Russell P (2002) Genetic Pearson Education (Inc San Francisco) 187–189

Tamura K, Stecher G, Peterson D, Filipski A, Kumar S (2013) MEGA6: molecular evolutionary genetics analysis version 6.0. Mol Bio Evolu 30:2725–2729

Saitou N, Nei M (2016) The neighbor-joining method: A new method for reconstructing phylogenetic trees. In Bibinu BS, Yakubu A, Ugbo SB, Dim NI Computational molecular analysis of the sequences of BMP15 Gene of ruminant and non ruminant. Open J of Genetics 6(2): 39–50

Felsenstein J (1985) Confidence limits on phylogenies: an approach using the bootstrap. Evolution 39:783–791

Tamura K, Nei M, Kumar S (2004) Prospects for inferring very large phylogenies by using the neighbor-joining method. Procee Natl Acad Sci 101:11030–11035

Ibrahim RS, Maiangwa J, Idris S, Musa J (2024) Production of cellulase enzyme by Bacillus Sp and Pseudomonas SP isolated from Antihill soil. Sci Word J 19(1):253–258

Devis MC, Kumar MS (2012) Production optimization and partial purification of cellulase by Aspergillus Niger with paper and timber sawmill industrial wastes. J Microbiol Biotechnol Res 2:120–128

Mandels M, Andreotti R, Roche R (1976) Measurement of saccharifying cellulase. Biotechnol Bioengin Sympo 6:21–33

Ghose TK (1987) Measurement of cellulase activities. Pure Appli Chem 59:257–268

Miller GL (1959) Use of Dinitrosalicylic acid reagent for determination of reducing sugar. Analyti Chem 31:426–428

Mandels M, Weber J (1969) The production of cellulase. In: Cellulase and their application. Hajny G J & Resse E T (ed.) Emerican Chem Society Adv Series,95: 391–414

Farinas CS, Loyo MM, Junior AB, Tardioli PW, Neto VB (2010) Finding stable cellulase and Xylanase: evaluation of the synergistic effect of pH and temperature. New Biotechnol 27:810–815

Saini R, Kumar SJ, Mukund GP, Patel AK, Mathur A, Deepak KT (2015) Enhanced Cellulase Production by Penicillium oxalicum for Bio-ethanol Application. Bioresource Technolo, 188 https://doi.org/10.1016/j.biortech.2015.01.048

Yadav PR, Chauhan PB, Grahlout M, Prajapati H (2016) Isolation, screening and optimization of process parameters for enhanced production of cellulase by solid state fermentation. Int J Adv Res Biol Sci 3(5):21–27

Legodi LM, Grange DL, Jansen V, Rensburg EL, Ncube I (2019) Isolation of cellulose degrading fungi from decaying banana pseudostem and strelitzia alba. Hindawi Enzyme Research, 2019(1390890):10. https://doi.org/10.1155/2019/1390890

Raul D, Biswas T, Mukhopadhyay S, Kumar Das S, Gupta S (2014) Production and Partial Purification of Alpha Amylase from Bacillus subtilis (MTCC 121) Using Solid State Fermentation. Biochem Res Internati, 2014(568141):5 https://doi.org/10.1155/2014/568141

Antika B, Jureeporn K, Chanaporn T, Pilanee V, Preeyanuch S, Nanthavut N (2024a) Cellulase production under solid -state fermentation by Aspergillus Sp. IN5: parameter optimization and application. Heliyon 10(5). https://doi.org/10.1016/j

Jadhav AR, Girde AV, More SM, More SB, Saiqua K (2013) Cellulase production by utilizing agricultural wastes. Res J Agric Forestry Sci 1:6–9

Gonzalez JM, Aranda B (2023) Microbial growth under limiting Conditions-Future perspectives. Microorganisms 11(7):1641. https://doi.org/10.3390/microorganisms1107164

Mran M, Anwar Z, Irshad M, Asad MJ, Ashfaq H (2016) Cellulase Production from Species of Fungi and Bacteria from Agricultural Wastes and Its Utilization in Industry: A Review. Advances in Enzyme Research, 4, 44–55. https://doi.org/10.4236/aer. 2016.42005

Antika B, Jureeporn K, Chanaporn T, Pilanee V, Preeyanuch S, Nanthavut N (2024b) Cellulase production under solid-state fermentation by Aspergillus Sp. IN5: parameter optimization and application. Heliyon Volume 10(5) 15 March 2024, e26601. https://doi.org/10.1016/j.heliyon.2024.e26601

Siti M, Abdullah A (2018) Cellulase Enzyme Production From Rice Straw Using Solid State Fermentation and Fungi Aspergillus niger ITBCC L74. MATEC Web of Conferences 156(3–4):01010. https://doi.org/10.1051/matecconf/201815601010

Sulyman AO, Igunnu A, Malomo SO (2020a) Isolation, purification and characterization of cellulase produced by Aspergillus niger cultured on Arachis hypogaea shells. Heliyon. December 2020, 6(12):e05668. https://doi.org/10.1016/j.heliyon.2020.e05668

Qian Y, Zhong L, Sun Y, Sun N, Zhang L, Liu W, Qu Y, Zhong Y (2019) Enhancement of cellulase production in Trichoderma Reesei via distruption of multiple protease genes identified by comparative secretomics. Front Microbiol 10–2019. https://doi.org/10.3389/fmicb.2019.02784

Shahzadi T, Ikram N, Rashid U, Afroz A (2013) Optimization of physical and nutritional factor for induced production of cellulase by Co-culture solid- state Bio- processing of corn Stover. WSEAS Transacton Environ Develop 9:263–267

Darabzadeh N, Hamidi-Esfahani Z, Hejazi P (2018) Optimization of cellulase production under solid-state fermentation by a new mutant strain of. Trichoderma Reesei Food Sci Nutr 7:367–896

Sundarram A, Pandurangappa T, Murthy K (2014) α-Amylase production and applications: a review. J Appl Environ Microbiolo 2:166–175

Wita A, Bialas W, Will R, Szychowska K, Czaczyk K (2019) The influence of temperature and nitrogen sources on cellulolytic potential of microbiota isolated from National environment. Pol J Microbiol 68(1):105–114. https://doi.org/10.21307/pjm-2019-012

Rajoka MI, Malik KA (2017) Cellulase production by Cellulomonas biazotea cultured in media containing different cellulosic substrate. Bioreso Technol 59:21–27

Shahriarinour MM, Wahab MNA, Mohamad R, Mustafa S, Ariff AB (2011) Cyanobacterial biomass as N- supplement to oil palm empty fruit bunch (OPEFB) fibre for imorovement of cellulase production by Aspergillus terreus in submerged fermentation. BioResour 6:1696–1706

Vita TR, Indrianingsih AW, Maryana R, Wahono SK (2015) Effect of temperature and fermentation time of crude cellulase production by Trichoderma Reesei on straw substrate. Energy Procedia 65:368–371

Brick RM, Walker GM (2000) Influence of magnesium ions on heat shock and ethanol stress responses of saccharomyces cerevisiae. Enzymol Microb Tchnolo 26:678–687

Gomaa OM, Selim NS, linz JE (2013) Biochemical and biophysical response to calcium chloride stress in Aspergillus Niger and its role malachite green degradation. Cell Biochem Biophys 63:413–423

Behailu A, Abebe G (2018) Isolation, production and characterization of amylase enzyme using the isolate Aspergillus Niger FAB-21. Int J Biotechnol Mol Biology Res 9(2):7–14

Sulyman AO, Igunnu A, Malomo SO (2020b) Isolation, purification and characterization of cellulase produced by Aspergillus niger cultured on Arachis hypogaea shells. Heliyon 6 (12) 2020 e05668 https://doi.org/10.1016/j.heliyon.2020.e05668

Lian X, Chao H, Wan-feng P, Lv-rong T, Xiao-yan Y, Xue-fang C, Xin-de C, Long-long M, Yong C (2013) Efficient cellulase production from low-cost substrates by Trichoderma reeseiand its application on the enzymatic hydrolysis of corncob. Afri J Microbiol Res 7(43):5018–5024. https://doi.org/10.5897/AJMR12.1761

Durairaj S, Gunasekaran S, Poovanalingam TV, Durairaj R, Ahmed A, Rajakrishnan R (2022) Enhanced cellulase enzyme production by Aspergillus Niger using cellulase/iron oxide magnetic nano composites. J King Saud Univ– Sci 34:101695

Anita S, Somvir B, Arti D, Narsi RB (2021) Evaluation of cellulase production from Aspergillus Niger and Aspergillus heteromorphus under submerged and solid-state fermentation. Environ Sustani 4:437–442

Author Information

Department of Microbiology, University of Nigeria, Nsukka, Nigeria